Table Of Content

A good website that will cater to your needs for the hair salon business is a must! You can reach more potential customers and create a brand reputation while maintaining your vision to enhance confidence and wellness. It promises an “eco-friendly and ethical salon found in the heart of London”. It allows visitors to book online or call their business through the primary call-to-action on the hero header. The huge, gallery-like menus contribute to the website’s user-friendliness apart from the sticky header Butchers Salon implements. If you wish to see more of their Instagram stories and posts, it’s also accessible on the website.

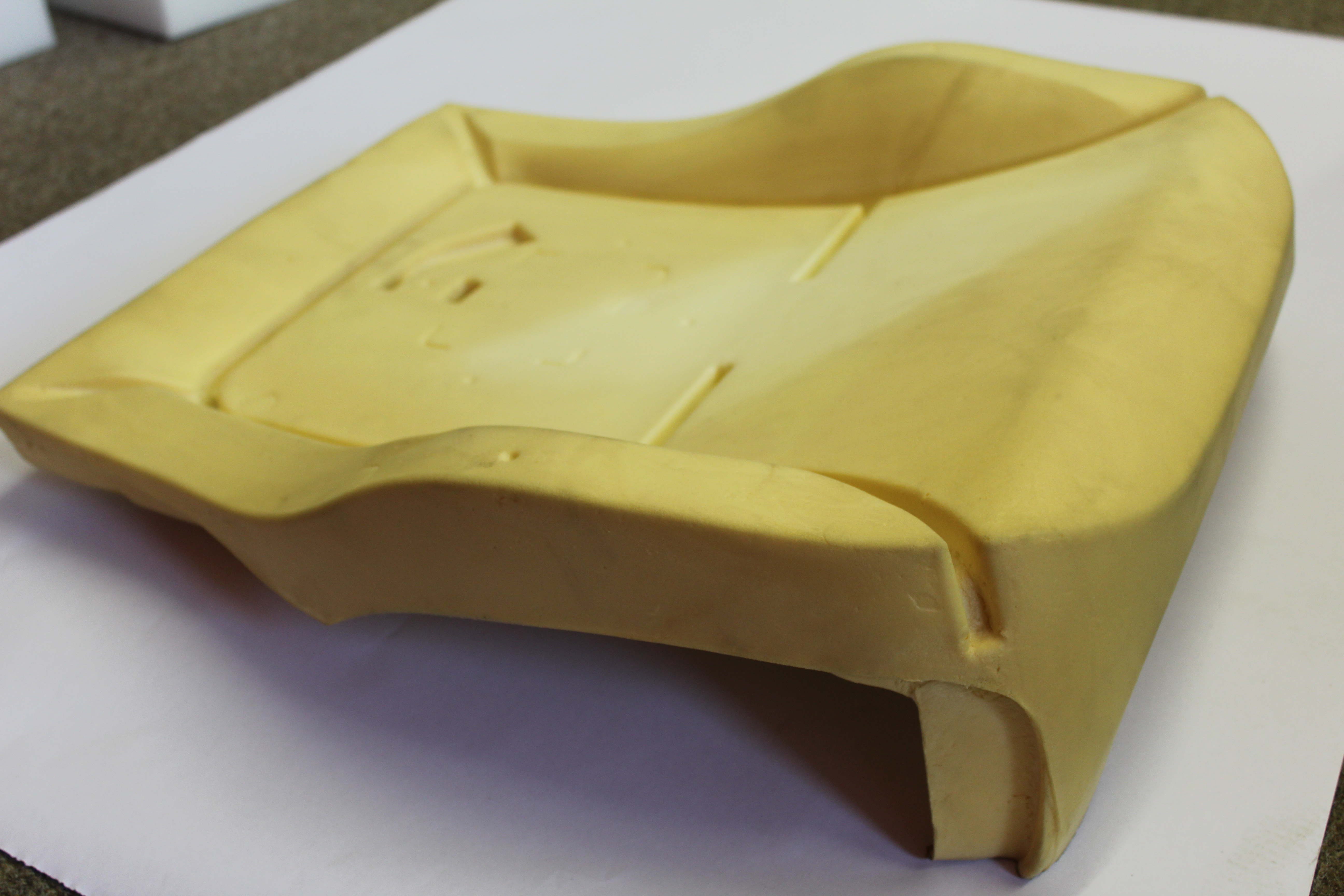

A Guide to Design-for-Manufacturing (DFM) Principles

And those who allow you to integrate often require you to add a box inside your website to host the booking widget. Although the latter can be ok, it often gets messy and looks strange depending on your website design and if users view it on mobile or in a desktop browser. Let’s dive straight into the top list of website builders for your service businesses. As we begin opening Meta Horizon OS to more device makers, we’re also expanding the ways app developers can reach their audiences. We’re beginning the process of removing the barriers between the Meta Horizon Store and App Lab, which lets any developer who meets basic technical and content requirements release software on the platform. App Lab titles will soon be featured in a dedicated section of the store on all our devices, making them easy for larger audiences to discover.

Tolerances →

Equally important to knowing reliability testing methods is to know how to accommodate reliability into a product. It is one of the most common and useful design for X categories as it provides techniques that help us create a better product at a lesser cost. Designers use them to enhance the design of parts, assemblies, and complete products. Designers improve a product’s design in all these areas by implementing certain design principles in the process. The aim is to create a product that excels in these areas by making changes in the proposed design. In cases where a physical iteration is needed, technologies such as rapid prototyping and generative design may be preferred.

Summary: Selecting The Right Software Is Vital To Maximizing Strategy

Common areas for increasing scope include product weight and dimensions, tooling, and labor costs. Optimizing these areas can also improve the organization’s overall efficiency. The early stage of the design process is the best time to implement DFM because it allows designers to make changes quickly and at a lower cost. Changing the design later is particularly difficult when it requires retooling. Thorough manufacturability evaluations are usually the first step in integrating DFM into the design.

Megaproject Trends For 2019: Yewande Akinola On The Next Frontier In Design - Forbes

Megaproject Trends For 2019: Yewande Akinola On The Next Frontier In Design.

Posted: Sat, 19 Jan 2019 08:00:00 GMT [source]

For example, engineering software from Siemens NX and CATIA from Dassault Systèmes enables the simulation of machining, casting and shaping, among other industrial processes. It provides a much-needed edge for engineering companies in today’s competitive market. It is easy to overlook DFM due to the lack of information, but research and case studies have shown that the proper application of DFM principles can guarantee stellar results. These tools enable deep DFM modeling and real-world testing at a fraction of the original cost. Thus, an increasing number of manufacturers are integrating DFM into their organizations to reap its many benefits. Each operation (flip of the part) has set-up time, machine time, time to load/unload tools, time to load/unload parts, and time to create the NC program for each operation.

Principles of DFM

Opting for a more straightforward manufacturing technique, such as injection molding, rather than CNC machining can lead to reduced production costs but less design flexibility. However, choosing a more specialized material with better qualities can raise material prices and lead times. Design for manufacturing (DFM) is the process of efficiently engineering or designing a product, usually in the product design phase, to lower production costs. DFM reduces the requirement for expensive production changes by preventing errors and discrepancies through early resolution of manufacturability concerns.

DFM is a great way to improve quality while cutting costs, but implementing it can present a challenge. This process consists of three distinct phases, including early integration of DFM, identifying additional opportunities, and broadening the scope of DFM. Serviceability is about making the product easier to maintain, including preventative maintenance and repairs. Engineers often do this by building features that show the product’s condition. For example, a compressor may include a sight glass that shows its oil level, facilitating preventative maintenance.

The following chart offers an excellent visual representation of the effect of an early DFM. As the design progresses through the product life cycle, changes become more expensive, as well as more difficult to implement. Early DFM allows design changes to be executed quickly, at the least expensive location. Incorporating surface mount technology (SMT) for components on printed circuit boards (PCBs) to streamline assembly.Designing PCB layouts with good thermal management to prevent overheating.

Mèche Salon

Synopsys helps you protect your bottom line by building trust in your software—at the speed your business demands. Synopsys is a leading provider of high-quality, silicon-proven semiconductor IP solutions for SoC designs. Synopsys is a leading provider of electronic design automation solutions and services. To generate in depth DFM insights, there is no substitute for detailed digital manufacturing simulation.

Effective communication and collaboration also help to ensure that the final product meets the requirements of both the design and manufacturing teams. By working together, designers and manufacturing teams can identify potential issues and make changes to the design to ensure that the final product is both high-quality and easy to manufacture. For a product's development to be a success, the design and production teams must work together. The Tesla Model S is an exemplary example of what can happen through multidisciplinary collaboration. With the engineering and design teams working together alongside other production specialists, they were able to maximize the efficiency of the assembly processes. The enhanced efficiency touched every part of the manufacturing process thanks to the use of state-of-the-art technologies like aluminum casting and robotic assembly.

A way to do this is by building in systems that show the real-time condition of a product. The sight glass allows for an engineer to check the oil level regularly and prevent any major breakdown. In design for assembly, designers implement qualities in a product that make it easy to assemble. Fewer, simpler components that can be easily assembled by simple operations are encouraged to eliminate the possibility of mistakes. As DFX considers many aspects of product development, the design team’s role is much bigger than one in traditional engineering design. DFX encourages greater collaboration between designers, suppliers, and manufacturers.

No comments:

Post a Comment